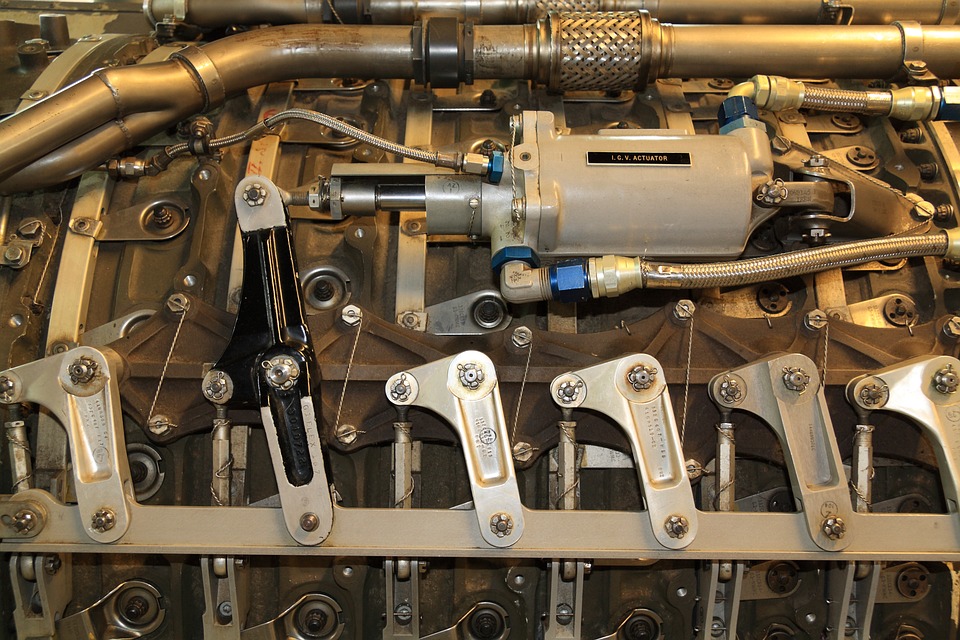

A hydraulic cylinder is a mechanical actuator that can be found in machineries like drilling machines, cranes, excavators, oil rig, loaders, etc. It helps in the process of moving or lifting heavy objects through exerting force in a ‘push’ or ‘pull’ fashion and it is powered by the pressurised hydraulic fluid.

Customised manufacturing

There are companies who manufacture hydraulic cylinders in Southampton and they offer a range of customisation options. They are also able to manufacture entire hydraulic systems for specific needs, be it in the industrial, marine or even the oil industry. There are many types of hydraulic cylinders like the single-acting, double-acting, telescoping hydraulic cylinders, etc. A company should have trained personnel to guide and advise you on which hydraulic cylinders are best suited for your needs.

Maintenance and care

Regular maintenance and care are needed for all your hydraulic parts if you want it to be working well. This can include periodic checks on the oil level and quality, the filter system, condition of the rod, uneven wear and tear, etc. Contaminated oil is the cause of most of the hydraulic failures today, and a simple oil check and change could have prevented that. It might be possible that uneven wear and tear of the rod could mean it is not aligned properly, as the rod is often used more on one side than the other. In such circumstances, it could be important to look for hydraulic cylinder repair firms in your area that might be able to re-align the rods.

Purchasing a spare

For companies who are often engaged in projects which have a tight deadline, it is recommended to purchase a spare hydraulic cylinder and have a trained person replace it when necessary. Many companies offer Fluid power products that include hydraulic cylinders, so procurement of such equipment should not be so difficult, as long as you find reliable suppliers. After all, approaching a company to repair or manufacture it may cause you a downtime which can lead to a delay. This, in turn, may incur monetary losses for the company.

Guarantee on products

When sourcing for a company, making sure that they offer a guarantee on their finished products is an important factor to consider. By providing a warranty period of at least a year, it showcases the company’s confidence that their product is of the highest quality. Some companies may offer a price that is lower than the market rate, but it does not come with a warranty due to the lower price. If there are any hydraulic repairs to be made, ensure that the company offers a warranty period too.

Getting the right support

Making sure that a company provides the after-sales support is necessary as you would want the fastest turnaround when it comes to any repair, manufacturing a hydraulic cylinder or a complete rebuild. The company needs to have trained staff to answer your questions, details to note in their products (like a maintenance checklist), and be on-site when necessary to do a survey if any repairs are needed.

The industry of repairing and manufacturing hydraulic cylinders is a relatively niche one as it requires highly trained professionals to be engaged in the process of it. Make sure you have done the required research on a company before engaging it, as a company run by incompetent personnel could be a costly affair for your operations.